Airsoft project part 1 | How to make a Piston Compressor

Video: https://youtu.be/ZvJ3V0CmaRI

stl download: https://www.thingiverse.com/thing:5362738

Chapter I — Plan

Airsoft gun, nerf gun. Those are a kind of very popular toy gun. As we know, the former shoot the 6mm or 8mm plastic bbs ammo and the latter shoot the nerf own soft ammo, which is softer, bigger and more safe than the bbs. They have very different ammo and basically they have very different shapes, but always they work on the same principle and it is shooting by compressed air or gas. In fact, airsoft has more ways to store the air or the gas. A part of them the power is from a mini co2 tank or the airsoft gas. Besides the co2 and airsoft gas, in many automatic electric airsoft guns there is a piston air compressor and that is the similar part with nerf guns. The electric airsoft’s compressor and the nerf’s are not very same but they have the same working principle indeed. Usually the piston was pushed by our hand or the electric motor.

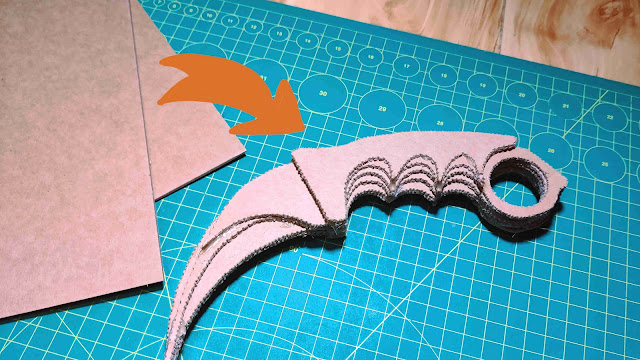

In addition, it seems the piston compressor is easy to build out with a 3d printer so this time I decided to use this device as the source of power for my 3d printed airsoft. Overall in this project there are 3 important parts which need to work out.

First of all, it’s the power of the blaster and I decided to use the piston compressor just like the nerf blaster.

Second, the ammo will be used by 6 mm soft rubber balls and the reason why I choose this kind of ammo is because it is small, soft and does not need too much power to shoot so that means this 3d printed airsoft gun will be more safe compared to the original airsoft gun.

Last one is the shape: I decided to use the shape of a Glock and let this 3d printed airsoft have a classic look. Ok that’s my plan for this 3d printed airsoft project.

Now, the only one thing is that the piston compressor is a very common device and does not have very complex structure but I never tried to build and model this kind of device and this is my first time to build a piston. In order to finally get the right compressor, so I called today’s video is [3d lab]. Finally I found the way to make this piston compressor and that looks not bad.

Chapter II — Blaster V1.0 beta

For the first try, I alway thought it’s very difficult to build a piston compressor with a 3d printer. Before that I always thought the 3d printed piston can’t compress air and the air can not be sealed inside the cylinder very well. But fortunately, it worked! After testing it, I found that although between the piston and the inside of the cylinder there is a gap, which is about 0.5mm, actually everything is good and the piston can blow out wind. So it also can shoot the bbs.

Chapter III — Blaster V1.0+ beta

Because I didn’t know if the device could work and I hoped not to see a waste when this device was made and it couldn´t work. After seeing the piston can work, I continued

my next step. That's an upgrade for it. I added a trigger for it and not a very different upgrade.

Chapter IV — Next Part

Next time, I’m planning to try to make a blaster and it will be the final version’s base;) I hope you can like this blog or video. See you next time.

support

Comments

Post a Comment